Radiant

Radiant Alloys

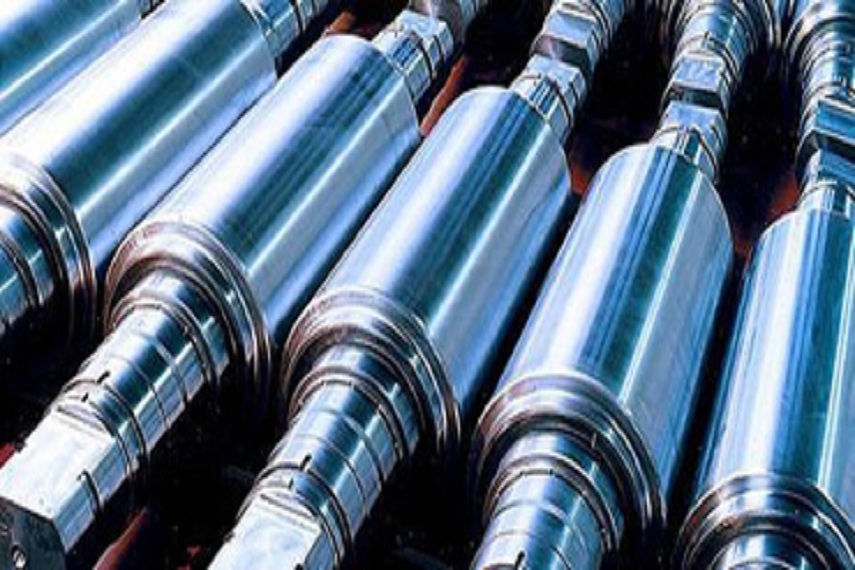

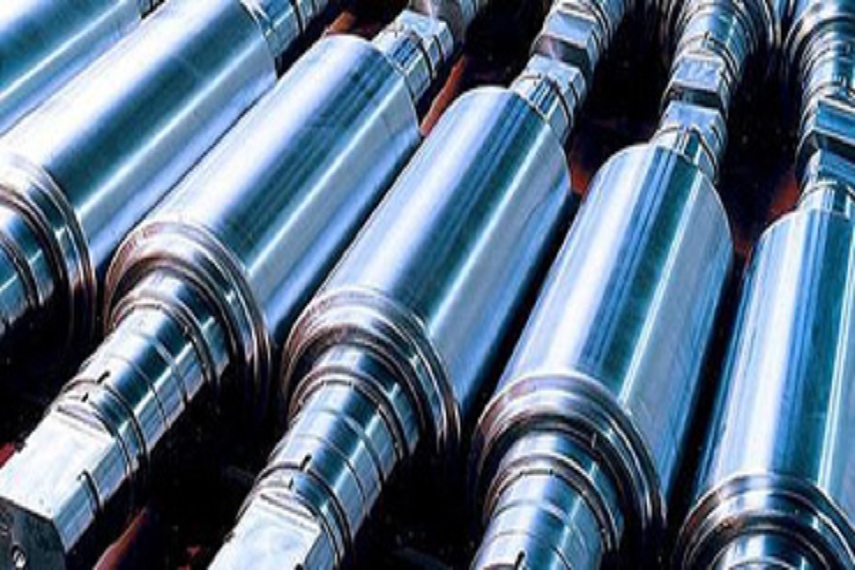

CASTINGS OF DIFFERENT TYPES OF ROLLS

S.G. Iron is considered as one of the most versatile rolls material now days. It is produced by a small proportion of magnesium added to the melt as nickel-magnesium or alternative alloys, or pure magnesium. In S.G. Iron rolls, the free carbon takes the shape of spheroids or nodules, thereby eliminating the notch effect to flake graphite and improving upon the mechanical properties of cast Iron. Application: Roughing and intermediate rolls for slabbing and blooming mils. Roughing, intermediate and finishing for rail and structural mills. Finishing for wire rod and narrow strip mills.

S.G. Pearlitic rolls: These materials consists of nodular graphite and carbiddes in a pearlitic matrix. The softest grades has a pearlitic matrix containing ferrite around the graphite nodules, while the higher hardness grades have a complete pearlitic matrix.

Application: Rolls for heavily loaded roughing stands, Rolling flat and wire rod.

S.G. Accicular Rolls: In many cases S.G. Rolls with an accicular matrix is preferred, because of its wear-resistance qualities. Materials consists of nodular graphite and carbides in under cooled austenitic pearlitic-bainitic matrix. The carbide content is considerably higher in the harder grades than the softer ones.

Application: Wire rod, Bar, Coil and medium section mills.

As the name implies, the barrel surface of these rolls does not show a clear chill layer but rather a gradual transition from a carbide rich structure containing a small amount of fine graphite at the surface to a grey core material. These Rolls ensure minimum sacrifice of clear chill while achieving maximum functional depth.

The transition from Chill to graphite being smoother, the gradual change in hardness associated with the indefinite-chill structure allows deeper grooving. Thus Indefinite Chill Rolls are superior in biting performance and have enough strength and resistance against thermal shock occurring at the time of failure in the rolling operation compared to other Chill Rolls.

The presence of the graphite improves spall resistance and also enhances resistance to fire cracking. These Rolls are available in Pearlitic matrix as well as Accicular/Bainitic matrix as well depending on the requirement of rolling mill.

These properties together with the excellent product surface finish make these rolls very suitable for applications where this feature is important.

Application: It can be used in both roughing and finishing stands for bar and sections, and for roughing, intermediate and finished stands of wire rod mills.